Mounting Systems

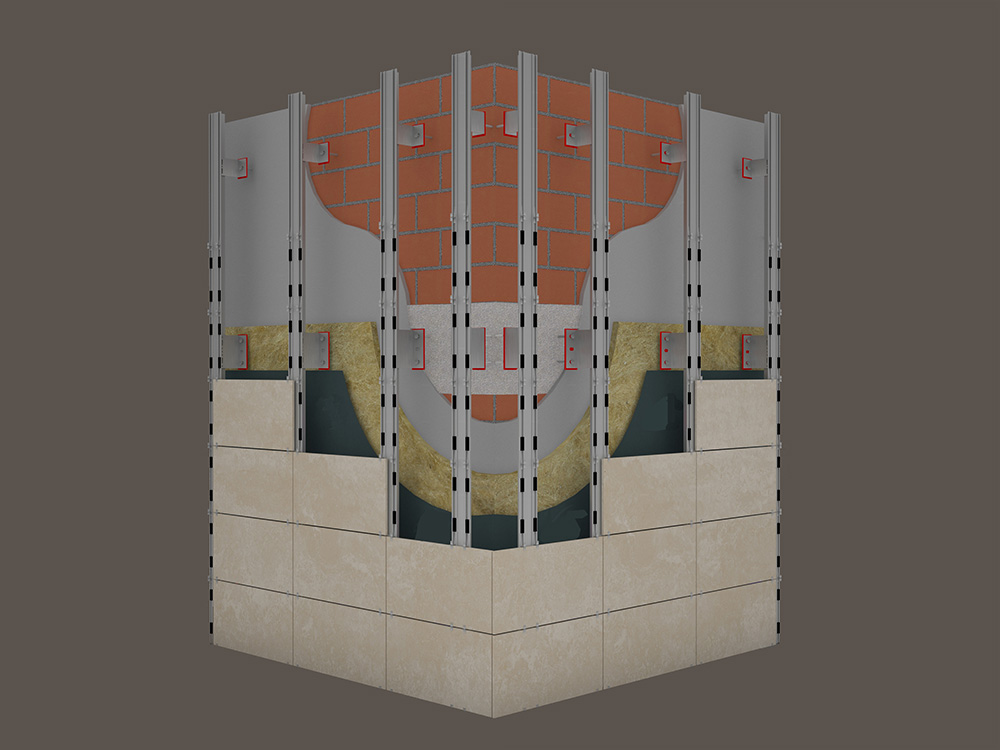

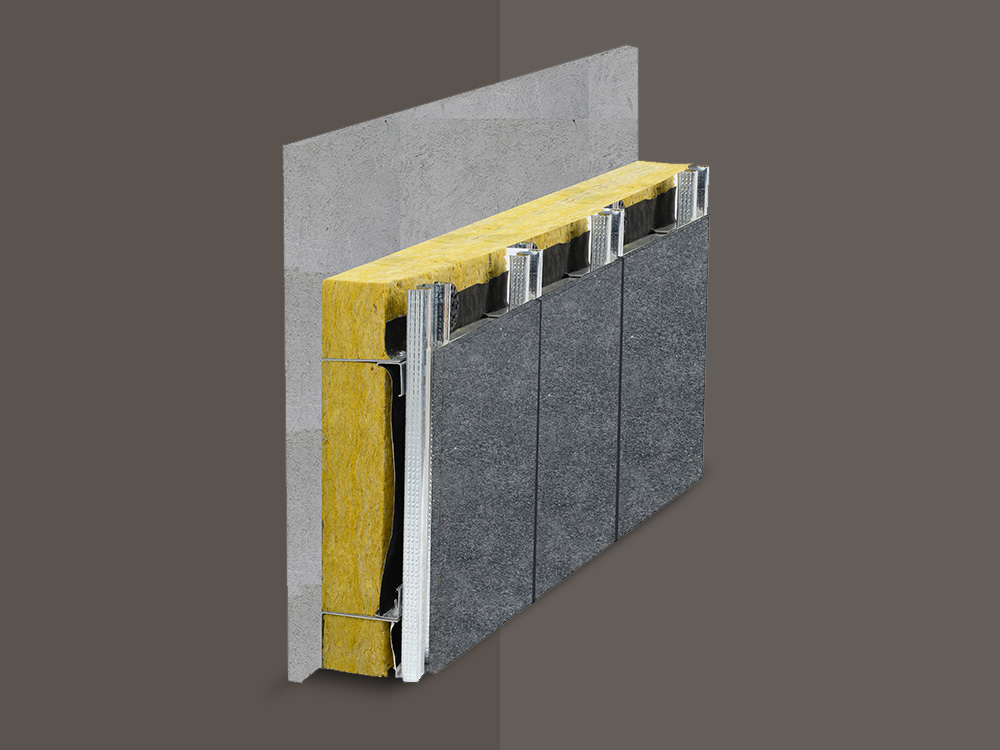

At bounding montage system firstly L and U anchors are mounted with anchorages according to the mounting surface (steel in the reinforced concrete) and anchor size appropriate to the dimension. In accordance with the project on it is make the installation of stone wool and moisture barrier to ensure thermal insulation and water tightness.

Anodized aluminum T profiles or galvanized sheet metal C profiles on U type anchors are used with trapezoidal screw according to the balance to fix L profile anchors. The profile surface is cleaned using a clean cloth with suitable chemicals (which have cleaning features). The same procedure is applied to the panel that will be mounted on the profile. Before the adhesive, an adherence enhancer Primer is applied to the cleaned surface. After the primer is dried, a front holder tape is mounted on the profile by taking measurements on the vertical. The tape adheres as a front holder until the adhesive cures and adjusts the thickness of the adhesive. Adhesive mastic which is set as the tip of the cannula is applied next to the front holding band. The surface protection on the tape is lifted and the plate is carefully placed and pressed by the hands as powerfully as the band at the low compression rate allows. Thus, the installation of the panel is completed.

Ekobord’s painted and pattern printed products are the best suitable for mounting with the adhesive system. The painting of these products can be done at the factory or at the building site before installation.

In the riveted mounting system, firstly the L or U anchors are mounted on the wall surface by using steel dowels. After that, in order to provide thermal insulation and waterproofing according to the project, rock wool and vapor barrier are installed. C profiles that are specially designed for L or U anchor channels or anodized aluminum T profiles are installed according to the project’s importance and fixed with trapezoidal screws according to the balance. Holes of fibre cement plates with a minimum thickness of 8 mm are drilled on the floor in accordance with the profiles. After the plates are placed in the profiles for mounting, new holes are opened from the holes to the profiles. Rivets are painted with the same color as the plate and mounted with rivet machine and the process is completed.

Ekobord’s natural-looking products can be mounted with a riveted system. Painting of these products is done after the installation and at the building site.

In the hanger mounting system, firstly the L anchors are mounted on the wall surface by using steel dowels. Then, in order to provide thermal insulation and waterproofing according to the project, rock wool and vapor barrier are installed. T profiles, which are specially developed for L anchor channels, are installed, leveled and fixed with trapezoidal screws. Aluminum hanger profiles are adhered to the back of fibre cement plates that have the thickness of at least 10 mm. Fibre cement plates with hanger profiles are installed on the T profile surface with the help of lentil head screws and the process is completed. Painted or patterned products of Ekobord can be mounted with the hanger system. Painting of these products can be done at the factory or at the building site before installation.

In the screw mounting system, firstly the L anchors are mounted on the wall surface with the help of steel dowels. Then, in order to provide thermal insulation and waterproofing according to the project, rock wool and vapor barrier are installed. M profiles are fixed to the L anchor channels, leveled and then fixed using trapezoidal screws. Fibre cement plates are fixed by screws on the M profiles. After the joints of the screw heads and the plates are puttied, the painting is done and the installation process is completed. Painting of these products can only be carried out on the building site after the installation and puttying.

In the clip-on mounting system, firstly the L or U anchors are mounted on the wall surface by using steel dowels. Then, in order to provide thermal insulation and waterproofing according to the project, rock wool and vapor barrier are installed. C profiles that are specially designed for L or U anchor channels or anodized aluminum T profiles are mounted and fixed with trapezoidal screws according to the balance. Clip hangers are mounted on T or C profiles and fibre cement plates are moved between them. Painting of these products can be done at the factory or at the building site before installation.

In the section hanger mounting system, firstly the U anchors are mounted on the wall surface with the help of steel dowels. Then, in order to provide thermal insulation and waterproofing according to the project, rock wool and vapor barrier are installed. C-profiles that are specially developed for U anchor channels are fixed with trapezoidal screws in accordance with the balance. The section hangers are mounted on the C profiles and the fibre cement plates are moved between these apparatus. Painting of these products can be done at the factory or at the building site before installation.

In this Tongue-and-Groove Mounting system, firstly the L anchor profiles are mounted on the wall surface by using steel dowels. Then, in order to provide thermal insulation and waterproofing according to the project, rock wool and vapor barrier are installed. The L anchor is fixed with anodized aluminum T profiles and mounted with trapezoidal screws. The tongue-groove hanger apparatus is mounted on the T profile and the tongue-groove fibre cement plates are moved between these apparatus. Painting of these products can be done at the factory or at the building site before installation.